Hence, the TMC incurred by the company in a quarter is $ 30,650, while the TMC per unit is $6.13. Takt time total indirect manufacturing cost is the rate needed to meet demand, cycle time is the time it takes to produce one unit, and lead time is the time from order placement to delivery. Learn all about different types of invoices through practical examples, and detailed explanations to ensure regular cash flow for your business. As a result, you’ll make informed decisions about future bids to clients and your internal cost calculations.

Production Volumes and Product Customization

- He’s not making as much profit as he’d hope and he thinks it’s because his coffee isn’t priced correctly.

- Total manufacturing cost per unit is the amount of money required to produce a single unit of a product.

- In his experience, the most common challenges are a lack of accurate data and the complexity of costing methods.

- The materials contribute to the final product and must be included in the cost calculation.

- Direct labor covers all employees directly involved in the preparation, assembly, and production of the goods.

- As we’ll explore briefly, excluding these expenses can cause you to exceed budget when planning future production cycles.

Modern manufacturing technologies such as robotics, Accounting For Architects IoT (Internet of Things), and AI (Artificial Intelligence) can enhance productivity and efficiency. For instance, automated assembly lines can improve throughput and consistency while requiring fewer manual interventions. Advancements in technology have revolutionized manufacturing processes across industries. Adopting modern technologies such as automation, robotics, and advanced manufacturing techniques can streamline operations, improve efficiency, and reduce labor costs.

Best Practices for Controlling the Costs of Manufacturing

By accurately calculating this cost, manufacturers can better price their products, optimize production, and improve operational efficiency. Direct labor is the cost of hourly wages of production workers who assemble manufactured goods. Businesses can improve profitability by lowering operating expenses through accurate and disciplined cost accounting and management.

- This reduction in raw material costs directly contributes to improving your overall cost structure and profitability.

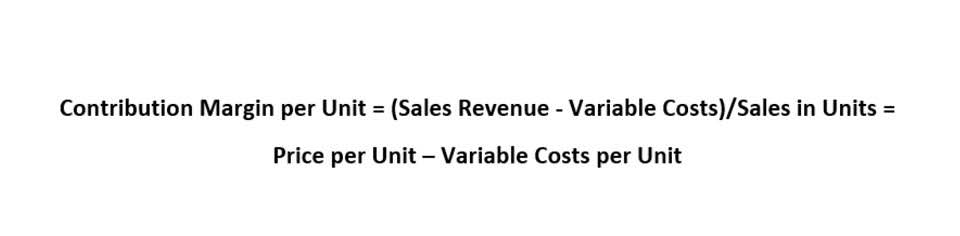

- It is computed by dividing the total manufacturing cost in a given period by the total number of units of a particular commodity produced in that period.

- Sometimes, a worker may represent direct labor when they’re involved in making a product, but their non-product duties, like sweeping the shop floor, would be indirect labor.

- This Manufacturing Overhead Cost Per Unit needs to be added to the direct material and direct labor costs to determine the full Cost of Goods Manufactured for each unit.

- That overhead absorption rate is the manufacturing overhead costs per unit, called the cost driver, which is labor costs, labor hours and machine hours.

- Company C pays rent worth $2,000 for a production unit, $5,000 as salary to the workers and employees working in the firm, and has machinery worth $1,000 to manufacture goods.

- Regularly reviewing this alignment at the end of a set period provides a crucial opportunity to assess the accuracy of your production cost estimations.

More clarity around financial health

Even though they’ll require additional materials for production beyond those already in the carpenter’s inventory, they will retain some of those materials after the product is finished. The general rule of thumb is that as production volume increases, the cost-per-piece decreases. This is true for stable and long-term production, where all the processes have been optimized for maximum efficiency and cost savings. Other raw materials, like food ingredients, have a limited shelf life, so they must go into production quickly or be preserved somewhere to prevent spoilage or contamination. Now that we understand how to group the components of manufacturing, let’s examine the different factors that affect the cost of manufacturing. Lastly, burden rate calculations will enhance your overall decision-making process and make tough decisions easier.

Determine Allocation Method (e.g., machine hours, labor hours)

To make the matter even more complicated, direct and indirect expense categories can vary among different industries and even within the same business. Some of the best ways to control the cost of manufacturing are through machine-augmented manual work and automation of repetitive CARES Act tasks. The best part of machine automation is that, unlike human labor, it provides consistent and repeatable performance without the added expense of breaks, injury, fatigue, or illness. Savvy factory managers use these strategies to control the cost of manufacturing in their facilities.